Inkjet printers all utilise one of the following ink types.

Dye Inks: Dye inks are water based where the dye is dissolved in a water base. Dye inks produce stunningly vivid prints but at the expense of increased fade rates. The reason behind the vividness lies in the way in which light is reflected to the eyes. Dye inks are absorbed into the paper and lay flat. Light bounces directly back to the eye producing a visually vivid image. At a microscopic level there is a great deal of space between the molecules and UV light (together with ozone gases) breaks down the connecting bonds which results in fading.

Strikingly vivid prints, bigger colour range (gamut), price.

Fade rates, colour shifts.

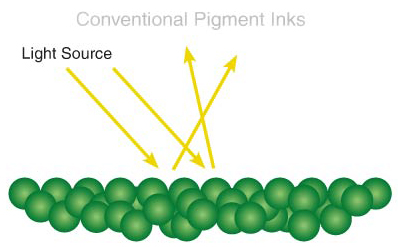

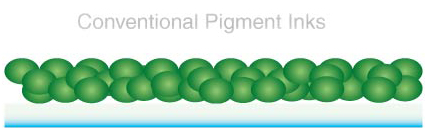

Standard Pigment inks have a very good fade life (in the order of 20 times dye inks) but tend to look a little duller than dye inks. Pigment inks essentially form bubbles on the paper surface and this causes light to reflect in various directions and not directly to the eye. This results in prints looking a little dull when compared to dye ink prints.

Pigment ink does not absorb into the paper like dye inks and thus produces a sharper image and text with

considerably less bleed however is easily scratched.

The print life is outstanding, virtually no bleed.

More costly, easily scratched, tend to look dull compared to dye prints. |

| |

|

Photo Pro Pigment Inks are the top of the tree in photographic inkjet inks. With professional photographers in mind rihac set out to produce an enhanced pigment ink which fit the following criteria:

- Resin Encapsulated (To maximize pigment suspension)

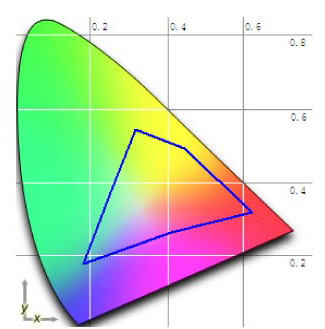

- Produces the full Adobe RGB gamut (More colours -wider gamut)

- Commercial quality light fastness (fade rate)

- Heat/Age particle swelling minimized

- No metameric failure (colour change under different lighting)

- No bronzing

- Scratch resistant

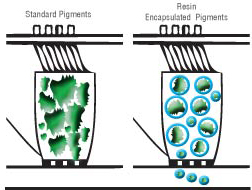

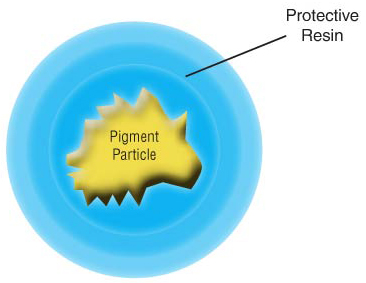

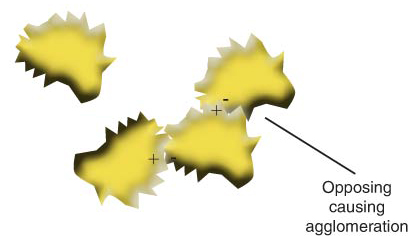

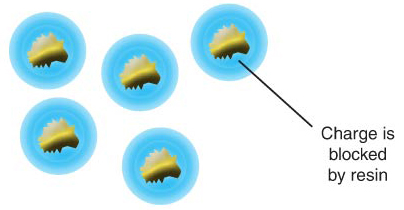

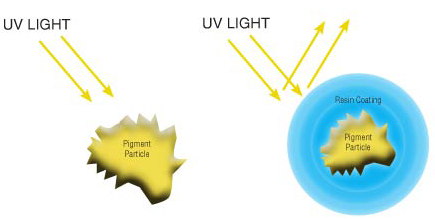

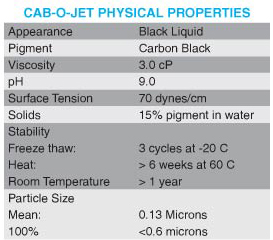

Photo Pro inks are a resin encapsulated pigment ink utilizing Cabots CAB-O-JET® patented pigment dispersions. Resin encapsulation is process where the pigment crystal is coated in a resin polymer. This technology prevents coagulation and settlement issues as it prevents agglomeration, the attraction of electrically charged particles. It also prevents the crystals from catching and bonding which is an issue with traditional pigment inks. The resin coat allows them to roll of each other creating a smooth flowing ink with even particle distribution.

A greater colour gamut (increased colour range) is achieved as the pigment particles are not clumped and thus are more evenly distributed when in suspension. Because of this rihac Photo Pro inks are suitable for printing on resin coated glossy media which can produce prints of near equal vividness of dye inks. The resin also acts as a bonding agent for the papers allowing the inks to adhere to the surface making the prints far more scratch resistant than other inks. Light fastness is increased due to two primary factors. Firstly the Cabots CAB-O-JET® dispersions already have an outstanding fade rating as per the DIN 54004 scale but also the resin protects the pigment particles minimizing UV light damage.

rihac Photo Pro series inks are available for all Epson branded printers including the Pro series large format

printers and home printer range

|

| |

Standard pigment crystals tend to catch on each other (agglomeration) causing larger particle size which

leads to blocked print heads and other printing problems. By coating the pigments in a resin it allows them

to flow smoothly from the print head as the particles roll off each other. |

|

|

| |

Resin encapsulation is process where the pigment crystal is coated in a resin polymer. This technology prevents coagulation and settlement issues as it prevents agglomeration, the attraction of electrically charged particles. |

|

|

| |

Cabots CAB-O-JET® dispersions already have an outstanding fade rating as per the DIN 54004 scale

but also the resin protects the pigment particles minimizing UV light damage. |

|

| |

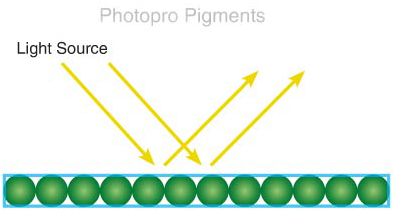

The even distribution of particles results in a higher colour gamut and higher gloss giving a smooth image

appearance. Conventional pigment inks often have a uneven distribution resulting in a lower color gamut. |

|

|

| |

Conventional pigment inks lay on top of media and scratch easily. Photopro pigments are fixed on media

by the polymerizing resin making them more durable and scratch-resistant. |

|

|

| |

A greater colour gamut (increased colour range) is achieved as the pigment particles are not clumped and thus are more evenly distributed when in suspension. Because of this the inks are suitable for resin coated glossy media which can produce prints of near equal vividness of dye inks. |

|

| |

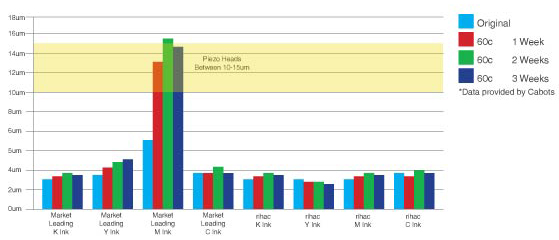

Particle swelling due to heat or age is a significant issue with aftermarket inks. This issue is typical of those inks imported from Asia and introduced to the market via places like Ebay. The ink viscosity and particle size must allow the ink to exit the print head. Marketing of pigment inks do not mention particle swelling which results in constantly blocked print heads and can cause irreparable damage to printers over time. When developing our inks we focused on ensuring particle sizing increases were minimized over the life of the ink. |

|

| |

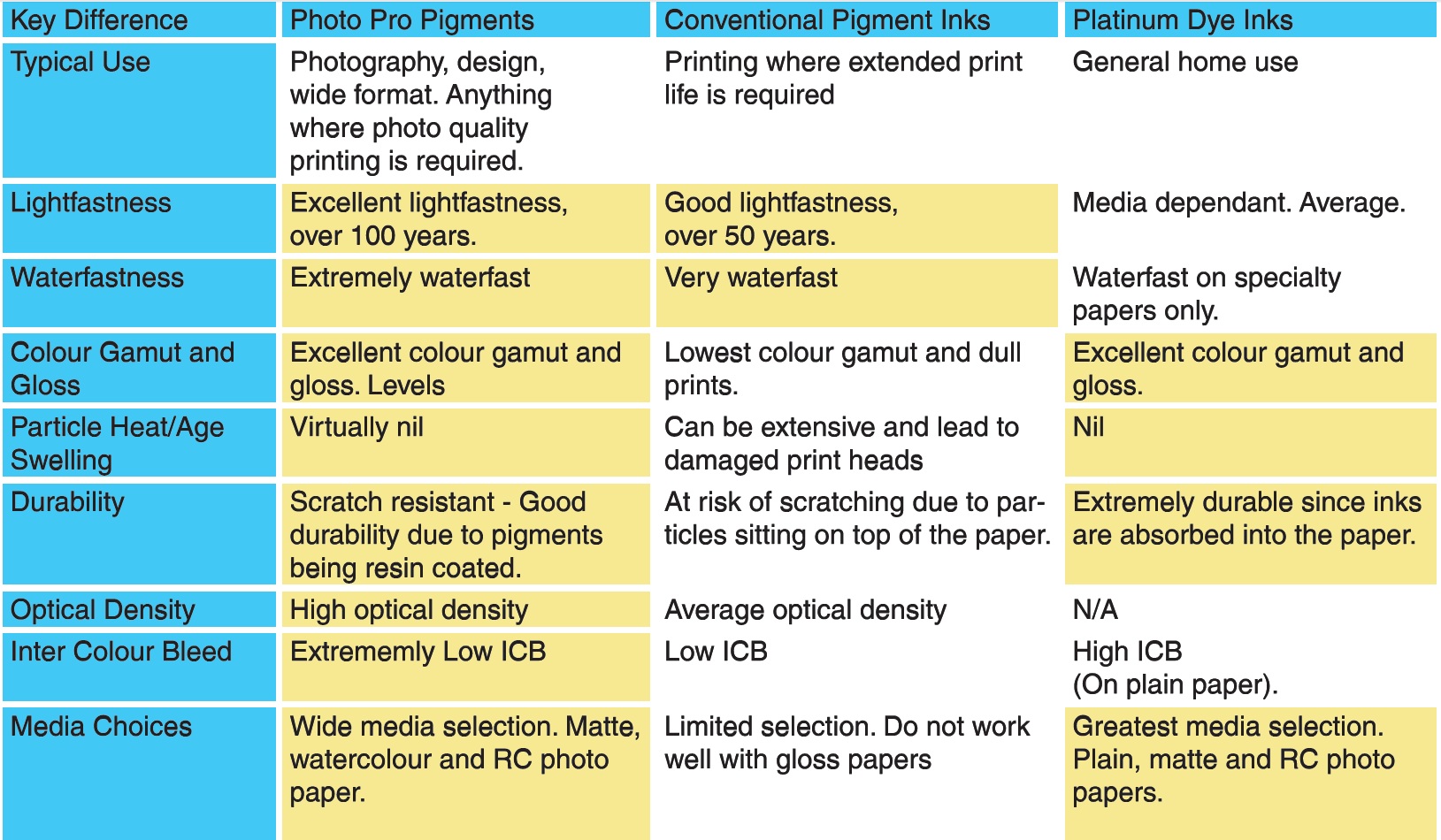

| The chart below demonstrates how rihac Photo Pro Pigments combine lightfastness, stability and waterfastness advantages of conventional pigment inks with the colour gamut, durability and wide media selection advantage of dye inks. |

| |

|

| |

Cabot's proprietary surface modification technology allows for the attachment of functional groups to the surface of the pigment particle. This attachment technique results in the highly reliable and stable dispersions. As the stabilizing groups are attached to the surface of the pigment particle, there are no polymers or surfactants in the bulk of the dispersion that can adversely effect properties such as viscosity and surface tension or contribute to foaming and kogation.

This technology also allows for tight control of the pigment surface chemistry, which results in consistent,

high "on paper" perforce. Properties such as optical density, edge acuity, intercolour bleed, dry time,

mottle etc are controlled by the chemistry of the pigment and the ink formulation in which it is incorporated. |

| |

Pigment are minerals suspended in liquid thus slowly over time, pigment particles will fall out of suspension. Gently agitating the inks (cartridges) will redistribute the particles into suspension. A further reason for avoiding low grade pigment inks is that agitating can actually aggrevate the static charge causing agglomeration (bonding of the pigment particles). Printers using any form of pigment ink require regualr use, more so than a dye ink printer. The formulation of pigment inks is complex and and allowing a printer to remain inactive for prolonged periods can result in changes to the ink formulations fine balance. So deciding on a pigment ink printer does require some careful consideration and extra care. There are some basic steps you can take to prolong your printers life when using pigment inks:

- Gently shake your inks prior to filling your Inklink or refillable cartrdges

- If you do not use your printer every week, perform a power cleaning cycle.

- For extended periods of non use (two weeks or more), remove the cartridges and gently shake them prior to use and then perform a power cleaning cycle. |

| |

CAB-O-JET 400, a new unique pigment

dispersion based on Cabot's latest surface

modification technology, suited for both thermal and piezo inkjet print heads. CAB-O-JET 400

Black pigment dispersion offers great formulation

flexibility for the inkjet in developer, enabling

outstanding step-change performance on

plain paper in the areas of:

• Paper Independence

• Optical Density

• Print Durability

• Intercolour Bleed

• Lightfastness

• Waterfastness |

|

| |